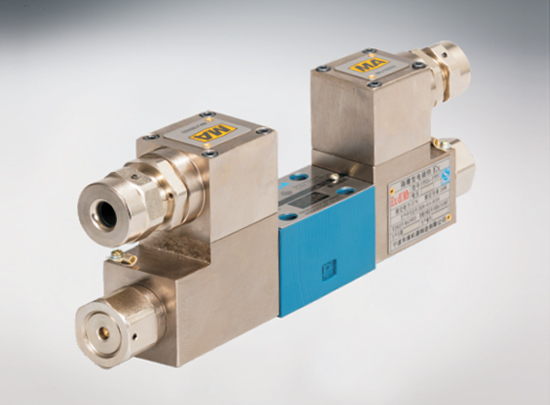

Proportional Pilot-Operated Relief Valve: A Key Component in Hydraulic Systems

create_time:2025-07-16 author:

In the field of hydraulic control, the Proportional Pilot-Operated Relief Valve has become an essential component for maintaining system stability, efficiency, and safety. Unlike traditional relief valves that only provide on/off pressure control, proportional pilot-operated relief valves offer precise and adjustable pressure regulation, making them highly valuable in advanced industrial applications.

This valve type operates by combining the principles of a pilot-operated relief valve with proportional control technology. The pilot stage receives an electrical input signal, which controls the valve opening proportionally. This enables the main valve to regulate pressure more smoothly and accurately, providing consistent performance even under fluctuating load conditions.

One of the primary advantages of a proportional pilot-operated relief valve is its energy efficiency. By adjusting system pressure according to real-time demand, it reduces unnecessary power consumption and minimizes heat generation. This not only enhances overall system performance but also extends the service life of hydraulic components.

Industries such as injection molding, metal forming, construction machinery, and aerospace rely heavily on these valves. For example, in injection molding machines, they allow precise pressure control during the molding process, resulting in improved product consistency and reduced material waste. In mobile machinery, they ensure smoother operation by preventing sudden pressure spikes that could damage equipment or compromise safety.

Another benefit is the valve’s compatibility with electronic control systems. When integrated with sensors and controllers, a proportional pilot-operated relief valve can form part of a closed-loop system. This means real-time feedback is constantly monitored, and the valve automatically adjusts to maintain optimal pressure levels. Such smart control capabilities are crucial in modern automation and Industry 4.0 environments.

Furthermore, proportional pilot-operated relief valves are designed for high reliability under demanding conditions. Their construction allows them to handle high pressures and large flow rates without sacrificing precision. This makes them particularly suitable for heavy-duty equipment that must operate continuously in challenging environments.

In conclusion, the Proportional Pilot-Operated Relief Valve is more than just a safety device—it is a cornerstone of efficiency, precision, and durability in hydraulic systems. As industries continue to push toward smarter and more energy-efficient operations, the adoption of this technology is set to expand, cementing its role in the future of fluid power control.

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch