What Are the Two Common Types of Proportional Valves

create_time:2025-06-11 author:

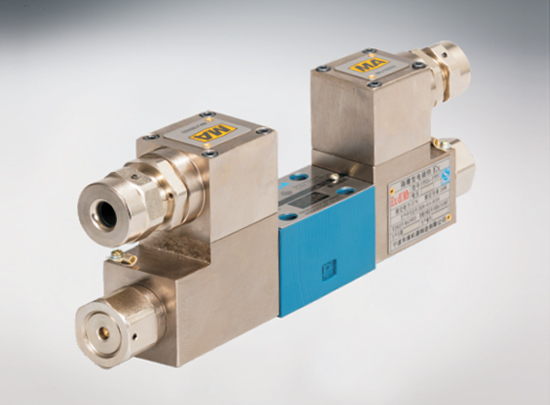

In modern hydraulic and pneumatic systems, proportional valves play a critical role in ensuring precise control of pressure and flow. Unlike standard on/off valves, these advanced components adjust fluid power smoothly based on electrical input signals, making them essential in industries that demand accuracy, efficiency, and flexibility. When discussing proportional valves, two common types stand out: proportional pressure control valves and proportional flow control valves.

Proportional pressure control valves are designed to regulate system pressure in direct response to an input signal. Instead of maintaining a fixed output, they vary pressure proportionally, which allows equipment to adapt to different load requirements. For example, in injection molding machines or metal-forming equipment, proportional pressure valves ensure that pressure remains consistent, improving product quality and extending the lifespan of machinery.

On the other hand, proportional flow control valves focus on adjusting the rate of fluid flow. By controlling how much fluid passes through a system, they directly influence actuator speed and movement. These valves are commonly found in mobile machinery, such as construction equipment, where precise control of cylinders or motors ensures smoother and safer operations. The proportional adjustment prevents sudden jerks or abrupt changes, which enhances both performance and operator comfort.

Both types of proportional valves rely on solenoid technology, where an electromagnetic coil responds to electrical signals to move the internal spool. Unlike simple solenoid valves that operate in only two positions, proportional valves can stop at multiple intermediate points. This fine-tuned operation allows for highly accurate performance across a wide range of industrial applications.

The integration of proportional valves with electronic controllers and sensors further expands their value. In a closed-loop control system, sensors provide real-time feedback, and the valve adjusts automatically to maintain optimal flow or pressure. This not only improves efficiency but also reduces energy consumption and minimizes mechanical stress.

In summary, the two most common types of proportional valves—pressure control and flow control—are essential for modern industry. By delivering adjustable and precise regulation, they support automation, improve safety, and help businesses achieve higher productivity. As industries move toward smart manufacturing and Industry 4.0, the importance of proportional valves is only expected to grow.

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch