Proportional Valve Series Driving Innovation in Fluid Control

create_time:2025-08-13 author:

In the evolving world of fluid power technology, the Proportional Valve Series has emerged as a cornerstone for precision control, energy efficiency, and system reliability. Unlike conventional on/off valves, proportional valves provide variable control of flow and pressure, making them indispensable across industries such as manufacturing, aerospace, automotive, construction, and energy.

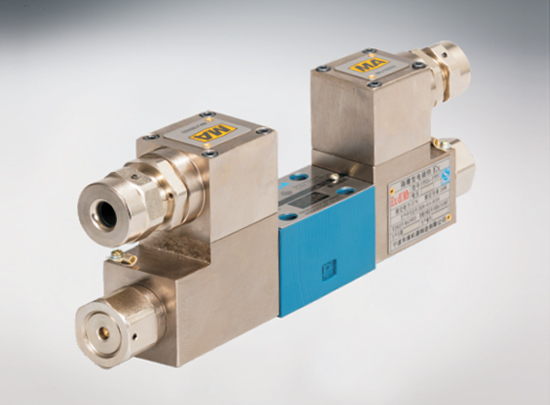

The Proportional Valve Series includes a wide range of valve types designed to meet specific application demands. Common products in this category include proportional pressure control valves, proportional flow control valves, and proportional directional valves. Each type functions on the principle of regulating valve opening in direct proportion to an electrical input signal, ensuring smooth, responsive, and highly accurate system performance.

One of the key strengths of the series is its adaptability. In injection molding machines, for instance, proportional pressure valves guarantee consistent molding quality by finely controlling pressure during each stage of production. In mobile construction machinery, proportional flow valves deliver precise movement control, enhancing both safety and operator comfort. Meanwhile, proportional directional valves are vital in automation systems, where they control actuator motion with unmatched precision.

Energy efficiency is another critical advantage of the Proportional Valve Series. By adjusting flow and pressure only as needed, these valves minimize power losses and heat generation, contributing to lower operating costs and a longer service life for hydraulic components. This makes them highly attractive for industries looking to reduce energy consumption and align with sustainable practices.

Integration with electronic controllers and smart sensors further elevates the value of the Proportional Valve Series. When used in closed-loop control systems, the valves automatically adjust based on real-time feedback, ensuring optimal performance under varying loads. This capability supports the ongoing transition toward Industry 4.0, where connected and intelligent systems are redefining productivity and efficiency.

Another important feature of the Proportional Valve Series is its reliability under challenging conditions. Engineered to withstand high pressures, fluctuating loads, and demanding operating environments, these valves deliver stable performance in heavy-duty applications. Whether used in industrial production lines or mobile hydraulic systems, they help reduce downtime and improve equipment longevity.

Manufacturers are also advancing the design of the Proportional Valve Series with digital interfaces and diagnostic functions. These smart features allow operators to monitor valve performance in real time, identify potential issues before they escalate, and optimize system operation through data-driven insights.

In conclusion, the Proportional Valve Series represents a critical advancement in modern hydraulic and pneumatic control. By offering precision, efficiency, adaptability, and reliability, these valves are helping industries meet the growing demands for automation and sustainable performance. As technology continues to advance, the Proportional Valve Series will remain a key driver of innovation in fluid power systems worldwide.

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch