What is Industrial Hydraulic Valve?

create_time:2024-05-07 author:

In the realm of industrial machinery and systems, the term 'hydraulic valve' often surfaces as a critical component, pivotal in controlling the flow and pressure of liquid in hydraulic systems. But what exactly is an industrial hydraulic valve, and why does it hold such significance in industrial operations? This article delves into the essence of hydraulic valves, exploring their functionality, types, and the integral role they play within various industrial applications.

The Essence of Industrial Hydraulic Valves

At its core, an industrial hydraulic valve is a device that regulates the flow of a liquid (usually oil) within a hydraulic system. It does this by opening, closing, or partially obstructing different passageways. This regulation of liquid flow and pressure is essential for controlling the mechanical movement of parts of machinery, such as cylinders and hydraulic motors, which in turn, dictates the operation of the entire system.

Hydraulic valves are indispensable in industries that rely heavily on hydraulic systems for their machinery to operate efficiently. These industries include, but are not limited to, manufacturing, automotive, construction, and aerospace. The precision, reliability, and versatility of hydraulic valves make them a preferred choice in these sectors.

Functionality and Types

The functionality of hydraulic valves extends beyond mere regulation of liquid flow. They are also instrumental in directing the flow in a specific order to actuators, switching the input between different outputs, and relieving pressure within the system to prevent potential damage or system failure.

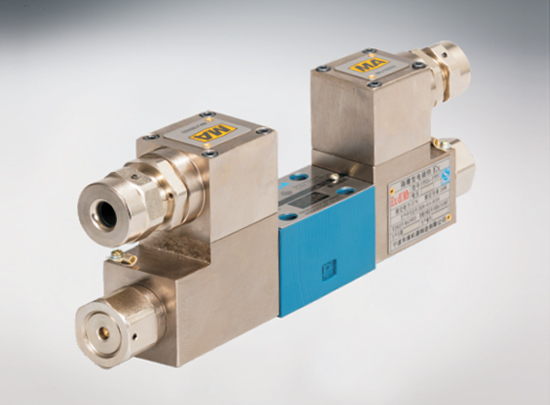

There are several types of industrial hydraulic valves, each designed to perform specific functions within a hydraulic system. The most common types include:

- Directional Control Valves: These valves control the path that the fluid takes from the pump to the actuators.

- Pressure Control Valves: As the name suggests, these valves help in maintaining or limiting the hydraulic pressure within the system to ensure safe operation.

- Flow Control Valves: These valves regulate the flow rate of the hydraulic fluid, thereby controlling the speed of the actuators.

Each type of valve comes in various designs and configurations, tailored to meet the specific requirements of different industrial applications.

The Integral Role in Industrial Applications

The integration of hydraulic valves in industrial systems brings about a multitude of benefits. Firstly, it enables precise control over machinery, allowing for smooth and accurate operations. This precision is particularly crucial in applications requiring meticulous movements, such as in robotic arms or CNC machines.

Moreover, hydraulic valves contribute to the safety and reliability of industrial systems. By regulating pressure and flow, they prevent situations that could lead to system failures or accidents, thereby ensuring the safety of both the machinery and the operators.

Lastly, the versatility of hydraulic valves allows them to be used in a wide range of applications, from simple machines to complex industrial systems. This adaptability, combined with their durability, makes them an invaluable component in the industrial sector.

In Conclusion, Industrial hydraulic valves are more than just components in a hydraulic system; they are the heartbeats that keep these systems running smoothly and efficiently. Their ability to control flow, pressure, and direction of hydraulic fluid with precision makes them indispensable in a vast array of industrial applications. As industries continue to evolve and machinery becomes increasingly sophisticated, the role of hydraulic valves is set to become even more critical. Understanding their functionality, types, and applications is essential for anyone involved in the design, operation, or maintenance of industrial hydraulic systems.

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch