- Products

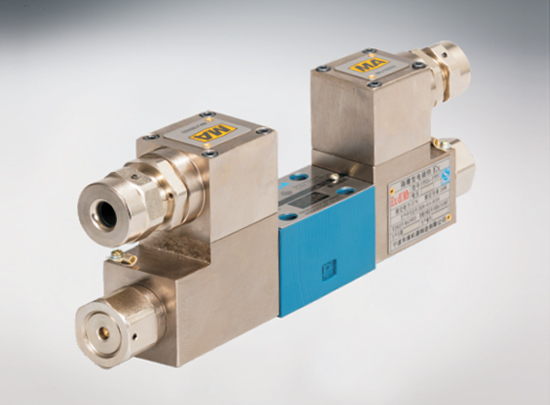

HY-TS38-20 (Proportional Relief Valve)

A screw-in, cartridge-style, direct acting, single stage, poppet-type hydraulic relief valve, which can be infinitely adjusted across a prescribed range using a variable electric. Pressure output is proportional to DC current input. This valve is intended for use as a pressure limiting device in demanding applications.

Operation:

The TS38-20 blocks flow from ① to ② until sufficient pressure is present at ① to offset the electrically induced solenoid force. With no current applied to the solenoid, the valve will free flow from ① to ②.

Note: back pressure on ② becomes additive to the pressure setting at a 1:1 ratio.

Technical specification (for application beyond these parameters, please contact with us)

|

Model |

HY-TS38-20 |

|

Installation position |

When possible, the valve should be mounted below the reservoir oil level. This will maintain oil in the armature preventing trapped air instability. If this is not feasible, mount the valve horizontally for best results. |

|

Storage temperature (℃) |

-20℃ to +55℃ |

|

Ambient temperature (℃) |

-20℃ to +50℃ |

Hydraulic specification

|

Max. operating pressure |

241 Bar (3500psi) |

|

Rated flow |

A: 11.4 lpm (3 gpm) at 20 bar (290 psi) pressure drop; B: 11.4 lpm (3 gpm) at 10 bar (150 psi) pressure drop; C: 11.4 lpm (3 gpm) at 5.5 bar (80 psi) pressure drop |

|

Flow path |

Free flow: ① to ② coil de-energized; Relieving: ① to ② coil energized |

|

Hysteresis (with dither of 250 Hz) |

3.3% (without dither: 7% maximum) |

|

Dither frequency |

150 Hz or higher |

|

Step reponse |

T on <50 ms; T off <7 ms |

|

Hydraulic fluid |

Mineral oil, phosphate-ester |

|

Fluids |

7.4 ~ 420 cSt (50 ~ 2000 sus) |

|

Temperature |

-40℃~+120℃ (-40~250°F), with NBR seals |

|

Cavity |

HY08-2, see page H.1.2 |

|

Max. pilot flow |

0.76 Lpm (0.2 gpm) |

Electrical specification

|

Max. Control current |

12 VDC coils: 1.10A; 24 VDC coils: 0.55A |

|

Relief pressure range (from zero to max. control current) |

A: 0-207 bar (0-3000 psi); B: 0-138 bar (0-2000 psi); C: 0-69 bar (0-1000 psi) |

|

Control signal |

DC or PWM (significant improvements in valve performance occur with superimposed dither, with either control method.) |

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch