- Products

PRODUCTS

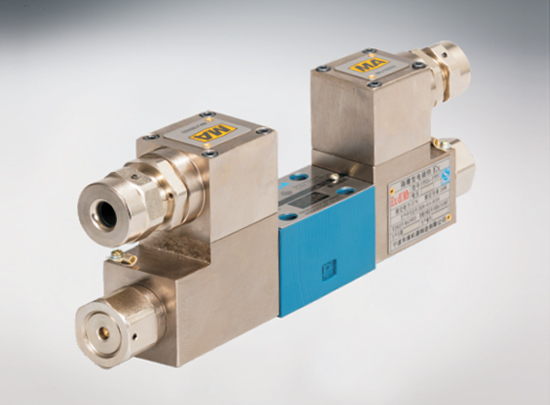

Hoyea has advanced processing equipment and hardware facilities, the products cover the whole fields of hydraulic components, including industrial valve series, mobile hydraulics, explosion isolation valves series, and hydraulic electronics...

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch